6.8.2024

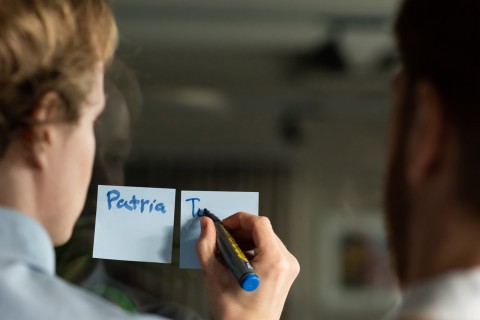

Patria’s vehicle deliveries are based on technology transfer – local partners handle vehicle manufacturing in the target country. This safeguards security of supply long into the future.

In recent years, Patria has received orders for the delivery of armoured wheeled vehicles to Poland, Slovenia, Croatia, South Africa, Latvia and Slovakia. All vehicle deliveries apply the same operating model based on close industrial cooperation with local operators.

This is founded on technology transfer, in which production is moved to the customer’s country either partly or in full. Local production of vehicles strengthens security of supply, as the capabilities to manufacture and maintain the equipment are available in one’s own country.

Local manufacturing creates expertise, jobs and tax revenue in the country

Local manufacturing also creates expertise, jobs and tax revenue in the country. A vehicle project is always carried out in line with the customer’s requirements. For instance, the customer might require that a certain percentage of manufacturing has to be carried out in that country, or that the project must provide the country with certain kinds of expertise.

In addition to the ordered products, Patria also provides its customers with long-term lifecycle service solutions, in which Patria and its partners take on responsibility for vehicle maintenance and repairs for an agreed period of time.

Patria has strict criteria in the selection of partners

Technology transfer and success in projects call for capable partners that can get things done cost-effectively and on schedule while meeting Patria’s high-quality requirements. Patria thoroughly assesses potential partner companies, analysing different aspects such as the expertise of their personnel, production facilities and corporate culture. Patria also requires its partners to comply with its ethical principles and the legislation of its business countries.

Depending on the project, Patria usually has a few main partners in the target country. However, a vehicle project can involve dozens of local companies when the main partners’ subcontractors are included.

Personnel of the partners also take part in the manufacturing

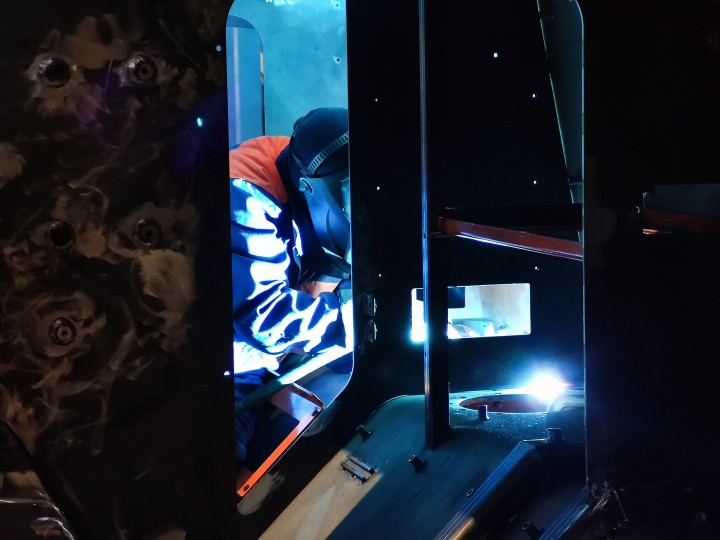

In projects, Patria handles the development and manufacture of the core technology of the vehicle platform in-house. These include, for example, the core components of the vehicle transmission and the dashboard, which includes the technology and software necessary for vehicle control.

The partner is provided with thorough orientation on production

A delivery project usually begins with the production of a prototype series. In the case of vehicles, this is carried out at Patria’s production plant in Hämeenlinna. Personnel of the partners also take part in the manufacturing – they are trained to make the product and provided with orientation on Patria’s operating models.

At the same time, the companies in the customer country that will be responsible for vehicle and sub-assembly manufacturing prepare to start up production. Project planning is an important phase – it involves reviewing the production processes, schedules and division of labour between the partners and Patria.

Another essential aspect of technology transfer is handing over the necessary manufacturing documentation to the local partner.

During the project preparation phase and the startup of production, Patria’s experts closely support the partner in technical questions concerning matters such as manufacturing or material procurements. If necessary, Patria will provide support later throughout the delivery project.

Long experience in technology transfer ensures success

The Patria employees in charge of technology transfer have decades of experience in their own areas of expertise. They have in-depth knowledge of the product and its manufacturing, thanks to which partners can be provided with smooth orientation on production.

Patria holds the main responsibility for production throughout the project

Once around five vehicles have been completed, the partner company is audited, and it is ensured that it can move ahead independently to the serial production phase. After that, annual audits are carried out to ensure that operational quality remains at the agreed level.

Patria holds the main responsibility for production throughout the project, even as local partners carry out the manufacturing. Patria’s technology transfer and local partnerships always set their sights on more than just single delivery projects. The aim is that when going forward, the partners can offer their products and services to a broader customer base as part of Patria’s global supply chain. Patria’s customers also benefit from this – an extensive cooperation network ensures security of supply and guarantees competitive prices.

What did you like about the article?

Thank you for your opinion! You can share the article on social media using the buttons below: